Global Advanced Recycled Circular Polyolefin Packaging and Durables Market Is Projected to USD 9,715.2 Million By 2036

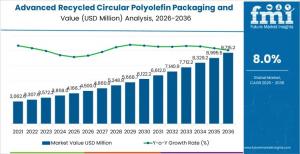

The advanced recycled circular polyolefin packaging and durables market is projected to grow to USD 9,715.2 million by 2036, at a CAGR of 8.0%.

NEWARK, DE, UNITED STATES, January 20, 2026 /EINPresswire.com/ -- The global advanced recycled circular polyolefin packaging and durables market is projected to reach an estimated USD 9,715.2 million by 2036, rising from USD 4,500.0 million in 2026. This robust 8.0% compound annual growth rate (CAGR) reflects a systemic shift by polymer manufacturers and global brand owners to implement molecular-level regeneration strategies that satisfy both high-performance engineering requirements and stringent environmental mandates.

As Extended Producer Responsibility (EPR) legislation expands globally, the industry is moving beyond basic mechanical recycling toward advanced chemical recycling pathways. These technologies enable the "upcycling" of complex waste streams—such as multi-layer films and contaminated plastics—into virgin-equivalent resins suitable for food-contact packaging and high-specification durable goods.

The 5 Ws: Defining the Circular Shift

• Who: Industry leaders including Borealis, LyondellBasell, Dow, SABIC, and ExxonMobil Chemical are spearheading the integration of advanced sorting and chemical processing.

• What: The expansion of advanced recycled polyolefins, specifically engineered to eliminate contaminants and restore polymer properties for multi-cycle use.

• When: A ten-year forecast window (2026–2036) marked by the scaling of chemical recycling feedstocks and mass-balance certification systems.

• Where: Global market activity is concentrated in the USA, Germany, China, Japan, South Korea, and the UK, driven by domestic waste-diversion targets.

• Why: Driven by plastic packaging taxes, corporate carbon-reduction commitments, and the need for materials that maintain structural integrity through repeated recycling loops.

Request For Sample Report | Customize Report | Purchase Full Report -

https://www.futuremarketinsights.com/reports/sample/rep-gb-31565

Technology Breakdown: Chemical vs. Mechanical Pathways

While mechanical recycling remains the foundation of the market with a 52.0% preference for clean waste streams, chemical recycling is the primary driver of new market value. By utilizing pyrolysis and depolymerization, manufacturers can now process "unrecyclable" mixed polyolefins into high-purity feedstocks.

Strategic Market Context: Material and Application Trends

The market is segmented by high-performance requirements:

• Recycled Polyethylene (PE): Captures 38.0% market share due to its essential role in flexible packaging and film applications.

• Recycled Polypropylene (PP): Holds 36.0% adoption, favored for rigid packaging and automotive durables where thermal stability is critical.

• Flexible Packaging: Represents the leading application at 30.0%, as brands seek to incorporate recycled content into high-volume film formats without compromising barrier properties.

Key Market Statistics (2026–2036)

• 2026 Market Value: USD 4,500.0 Million

• 2036 Forecast Value: USD 9,715.2 Million

• Projected CAGR: 8.0%

• Leading Application: Flexible Packaging (30.0% Share)

• Leading Certification: Mass-Balance (40.0% Share)

Global Growth Outlook: Regional Highlights

Regulatory frameworks and infrastructure maturity are the primary determinants of regional growth:

• China (9.2% CAGR): The world’s leading growth hub, supported by massive manufacturing scale and government policies integrating digital "waste-to-feedstock" tracking systems.

• USA (7.8% CAGR): Growth is driven by major corporate sustainability pledges and significant federal investment in domestic chemical recycling infrastructure.

• UK & Germany (7.7% & 7.6% CAGR): Leading the transition through high-performance architectural standards and "Plastic Taxes" that incentivize high recycled content in consumer packaging.

Traceability and Certification: The Rise of Mass-Balance

To maintain supply chain efficiency, Mass-Balance Certification has become the leading framework, commanding 40.0% of market adoption. This accounting-based approach allows manufacturers to co-process recycled and virgin feedstocks in existing large-scale facilities while providing verified sustainability claims to end-users through blockchain-based traceability.

Competitive Strategy: Beyond Material Cost

Suppliers are defending market share by providing "virgin-equivalent" guarantees and technical support for rapid product qualification. By aligning with brand owners earlier in the design phase, polymer producers are ensuring that recycled polyolefins are "designed-in" to the next generation of returnable packaging and long-life consumer durables.

Key Industry Participants

• Borealis

• LyondellBasell

• Dow

• SABIC

• ExxonMobil Chemical

• INEOS Olefins and Polymers

• TotalEnergies Polymers

• Braskem

• NOVA Chemicals

• Repsol

Similar Industry Reports

Advanced Recycled PE E-Commerce Packaging Market

https://www.futuremarketinsights.com/reports/advanced-recycled-pe-e-commerce-packaging-market

Recycled Polyolefin Compounds for Food Packaging Market

https://www.futuremarketinsights.com/reports/recycled-polyolefin-compounds-for-food-packaging-market

Advanced Packaging Market

https://www.futuremarketinsights.com/reports/advanced-packaging-market

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.